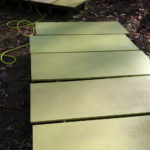

Recycling EPS (Expanded Polystyrene aka Styrofoam) to Make Solids Heavy Varnish for Sealing Wood Exposed to Rain and Standing Water.

Summary: This article describes a simple method for upcycling Styrofoam waste into a useful surface varnish. We will set the goals of durable, waterproof, easily tinted using household materials, and a reasonably good surface finish. I will discuss some of my reasons for the formulation given and also provide some alternatives for the solvent blend. We will also document some tests performed in case I return to this project later to reformulate as a glue which was one of the original paths planned for in this experiment.

Background – Why bother?

About a month ago we received a large package that used EPS as dunnage to protect the item being shipped. These massive chunks of Styrofoam seemed a shame to just throw away, so I slept on what to do with them.

The following morning I performed some experiments making a self-leveling “goop” I planned on applying to some 3D prints after a few experiments I found a way to get a consistent surface but the thick coating resulted in bubbles and adjusting the solvent blend to get rid of this issue resulted in slow dry times and frankly, UV resins do an adequate job so I moved on to making varnish as this also solved the base problems of thick coating.

The base blend was too “fast drying” and thick and resulted in a very poor surface texture so re-blending was needed to bring back both some self-leveling and improve the drying characteristics. This was resolved by adding xylene to thin and slow the drying of the final product.

Selecting a Base Formulation

Acetone disassociates polystyrene quite effectively but does not form workable solutions. It mostly creates a sticky goop of long polystyrene chains that sort of stack together at the bottom of the vessel. MEK is also effective, but acetone is cheaper, and evaporates faster, and therefore is ideal in the final product.

While many solvents truly dissolve polystyrene, toluene has a reasonable boiling point, a moderate evaporation rate, and can hold in solution more polystyrene than any other “common” hardware store solvent. It is however, getting hard to find and if you are unable to locate it, xylene is also effective, though it can not hold quite a concentrated solution, in our case we are using almost a 2x surplus of solvent so this is not an issue.

In the final product. we want a cosolvent containing mostly fast-drying acetone with a 25/30% toluene/xylene blend. The toluene/xylene blend will provide benefits to the surface finish as well as make the mixture a smooth consistent product. Again you can use straight xylene if needed, but dry times will be a little slower, you may experience more bubbles in the finish and the solution will not be clear as it would be with even a small fraction of toluene.

Batching and Improving Feed-Rate of EPS

I could not find a figure for how much EPS could be dissolved per ml of acetone and this is probably because we are not forming a true solution here, instead, we seem to be creating a suspension. Through small-scale experimentation, I found that after 5 grams of EPS was added to 10 grams of acetone (~7.857ml) the mixture would not accept any more EPS at what I would consider an acceptable feed rate. Material added mostly just sat on the surface or formed a clump on the side of the glassware.

I also experimented with pre-blending acetone, toluene, and/or xylene prior to dissolving the EPS and found the feed rate was always decreased when the blend was used. And again this makes sense as the acetone is disassociating the polystyrene leaving a concentrated acetone layer “floating” on top allowing for more and more disassociating. When we form a solution we dilute the solvent in contact with the base stock slowing the process. Secondarily when the solution becomes thickened air trapped in the EPS has a harder time moving to the surface raising the levels in the vessel and slowing the feed rate. EPS is mostly trapped air by volume therefore this must be taken into account. For these reasons we “dissolve” in straight acetone.

Once the acetone tank has processed as much polystyrene as it can, toluene and/or xylene can be added with agitation to form a solution that can be poured or drained from the vessel and the process can be restarted. Straight toluene seems to function best at this step, but the differences are marginal until scaled up to gallon batches.

The Final Formula – Brush-able Varnish with Acceptable Dry Time

The formula will be given in parts by weight and percent by weight. I will also give an example ~1.5-gallon (5.84 qt.) batch using ml/qt measurements. Depending on the outside temp at application time some thinning or dry time adjustment can be handy so I’m leaving ~1 qt. of free headspace in the F-Type gallon solvent can(s) I’ll be using.

Base Formula:

1.5-Gallon (volume) Batch:

Note 1: Remember to leave enough headspace in your storage container. I did not properly take into account the abnormal volume increase from the polystyrene in solution. It’s still not clear why the displacement was more than calculated. But my original large-scale batch overflowed the storage container resulting in losses.

Note 2: Properties are improved with a higher percent of toluene vs xylene and the ratio of the two can be adjusted as needed. The final formula strikes a reasonable balance between the added cost of toluene.

Processing – Lessons Learned

Weigh the acetone and feed it into a suitable vessel (I prefer a wide-mouthed glass jar with a lid). Ensure you have at least 25% headspace to allow for bubbles. More than 25% does not improve the feed-rate, but can make handling easier. EPS should be pre-ground or [as was in my case] cut into strips and feed into the vessel. The formulation allows for 15% excess acetone before the feed rate slows to unacceptable levels; you may adjust as needed.

Once all EPS base stock is fed into the vessel xylene ONLY is added. This will use just over 50% of the headspace and the vessel should be sealed and agitated until all of the material is fully taken into solution. Higher temperatures speed this process, a water bath would speed this process.] The thick liquid [around the consistency of Maple Syrup] was then transferred to the storage container

Note 1: This example was performed on a cold day with a solvent temp of about 37f/3c and the process took 10-15 min.

Note 2: At this point, I like to use the toluene to clean all glassware, funnels, and tools used. This will pull in any losses which occur using such a thick liquid.

The toluene is now added to the storage container. At this stage, agitation is not critical, after a short while the toluene will dispense throughout the “syrup” and thin the consistency. [At this point our consistency is around that of Elmer’s glue.]

Tinting and Coloring EPS Varnish.

The dissolved polystyrene in the fully blended solvents is now a transparent liquid with a slight white haze. This material is easily tinted with dyes or pigments. Four experiments were performed.

Tint’s all brand universal paint pigment:

Created a lovely transparent coating that looked wonderful on wood grain. 1 ml. of tint’s all tinted 2-3 fl-oz. of varnish. More could be added to deepen the colors.

Laser printer toner (polyester and pigments):

I have been using “toner” for epoxies for some time and found it dissolved well in this solvent blend. A gram of toner will lightly tint a pint of base material, but it can be added until the material is no longer transparent. Adding additional solvent will be necessary for deep colors using more toner as this will significantly thicken the solution as the polyester dissolves forming a copolymer.

Oil-based paint (Rust-Oleum Professional High Performance Protective Enamel):

I would call this “semi” compatible as it will change the varnish’s final surface characteristics some. The dried product is hard and durable, but the surface finish is more challenging and bubbles form from the addition of solvents used in the paint. This could be addressed.

Flake Aluminum (Standart Pyro UZ, or similar leafing flake):

Along with Tint’s All, this produced stunning effects, but due to the thick nature of this varnish, brush strokes will always be evident.

Note: Other fillers should be experimented with for adding properties such as wear resistance (Titanium powder, ceramics), UV resistance, and grit to produce added traction.

Other Figures, Tables, and Notes:

Displacement / Polystyrene Volume:

Polystyrene density: 0.96–1.05 g/cm3

Experimentally 600g of PS dissolved displaces 1 qt. of liquid (?)

(This is more than 33% more displacement than the density would indicate. Why?)

Solvent Densities:

Toluene: 0.865 g/mL.

Acetone: 0.7857 g/mL.

Xylene: 0.87596 g/mL.

Useful Conversions:

946.4 mL. in a qt.

4 qts. in a gallon

Mini batch – Thick Semi-transparent solution:

300g of acetone

150g of EPS

60 grams of toluene (this is the minimum to achieve a solution at 18c)

*Adding 3g xylene per 12g of the above mix yields a nice surface finish*

Current costs:

- Toluene costs $60 per gallon (after shipping)

- Xylene costs $25 (local pickup)

Other Solvents:

-add from notes-

Straight Xylene:

A test batch using straight xylene was slow to dry and displayed brush strokes after drying. Toluene while not required improves the workability of the final product.

Cleanup:

Cleanup with lacquer thinner causes PS to fill out of solution as a sticky mess. Cleanup with Xylene.

Next Areas to Explore:

- Crosslinking agents

- Epoxy Hardener

- Additives and fillers

- Plasticizers (try: diester-phthalate, glycol)